Call us: +49 (0) 2224 9883 181

Copyright © TiXX OHG. All rights reserved

Email: info@tixx-

TiXX OHG

Maarweg 30

D-

Germany

Upcoming Events

Save the Date

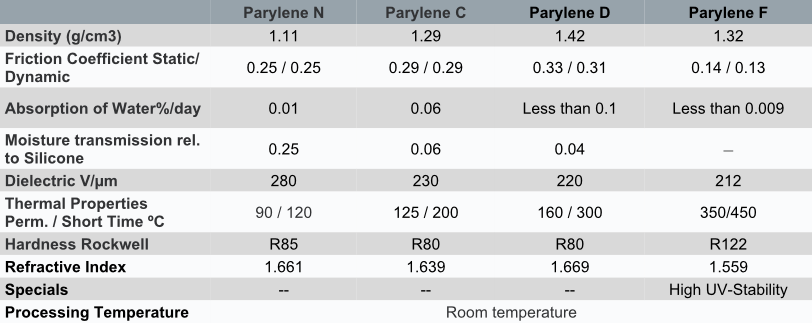

All Parylene coatings are created using a monomer deposition process in a vacuum chamber. The monomer condenses and polymerises on the surface and forms a conformal and uniform coating which follows the surface topology. The Parylene monomer is prepared outside the coating vessel which does not need to be heated and therefore the coating is applied at room temperature.

Our standard and most widely used Parylene coating. This is one of the most robust variants, which is also used to coat rare earth Magnets.

It protects against moisture and gas penetration. The additional chlorine molecule

on each monomer adds hydrophobic prop-

A high thermal stability coating for demanding applications which is extremely hydrophobic.

Often used in PCB applications for Automotive, Electronics, Aerospace and Defence applications.

This is an outstanding coating for silicone and other elastomers. Most commonly it

is used to coat printed circuit boards. This is the lowest cost coating which meets

most applicat-

This grade of Parylene has a very low dielectric strength making it suitable for electronic devices. It also has excellent penetration into small spaces and gaps.

Taking away pressure to get a thin polymere film

Get the best results with a small amount of Parylene

Parylene Coating

Plasma Coating

HFE/HFC Cleaning

Plasma Treatment

Parylene Coating

Plasma Coating

HFE/HFC Cleaning

Plasma Treatment

High thermal stability and over 2500 hours UV-

Often used in PCB applications for Automotive, LEDs, Aerospace and Defence applications.

Where your products become excellent

Parylene Coating Specialists